In-cylinder testing

In-cylinder testing is attempting to diagnose engine problems without starting to strip the engine down using modern test equipment and sensors. These techniques have gained ground but are still largely unexploited by many. They have the advantage of leaving the engine intact so leaving the potential fault undisturbed and helping to prevent unnecessary work and cost. In some instances they will reveal engine problems that are not detectable by other methods.The following demonstrates a couple of these techniques that 1BitHigh can perform.

Secondary (HT) voltage investigation

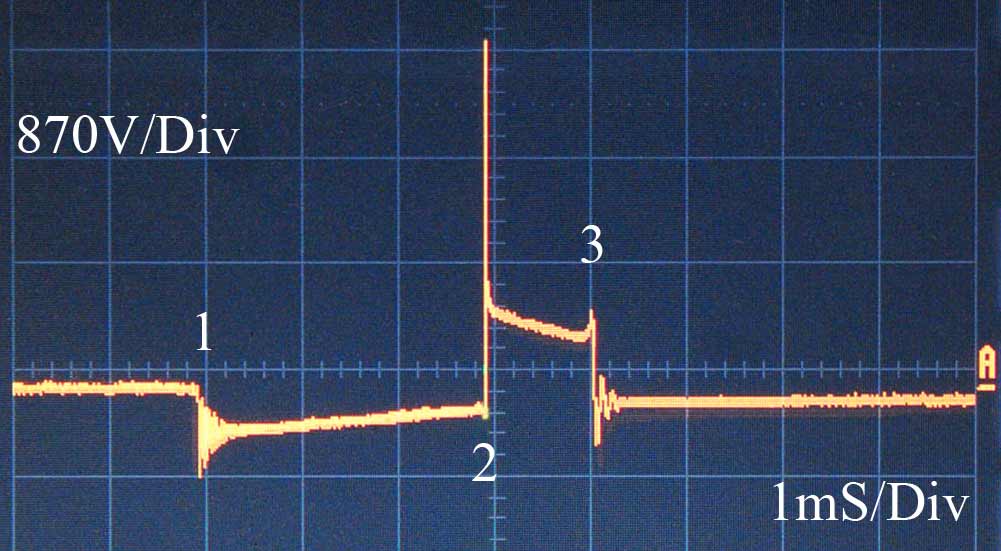

Fig 1 A fairly normal burn but possibly low compression as noted above.

(1) Here the ignition coil is energised, and over about 3mS the energy in it builds.

(2) The ignition coil is turned off and the voltage rapidly rises across the spark plug gap. Here it rises to about 3kV before it breaks down the gap and fires the plug/cylinder. The voltage taken to do this is often called the 'Firing voltage'. The cylinder starts to burn. The plug voltage falls and then stabilizes as it burns, and the 1mS-1.4mS burn time is fairly typical. This part of the voltage waveform is called the 'burnline'. As the burn ends the cylinder slightly leans out but the burn and coil energy are fairly well matched.

(3) The cylinder extinguishes.

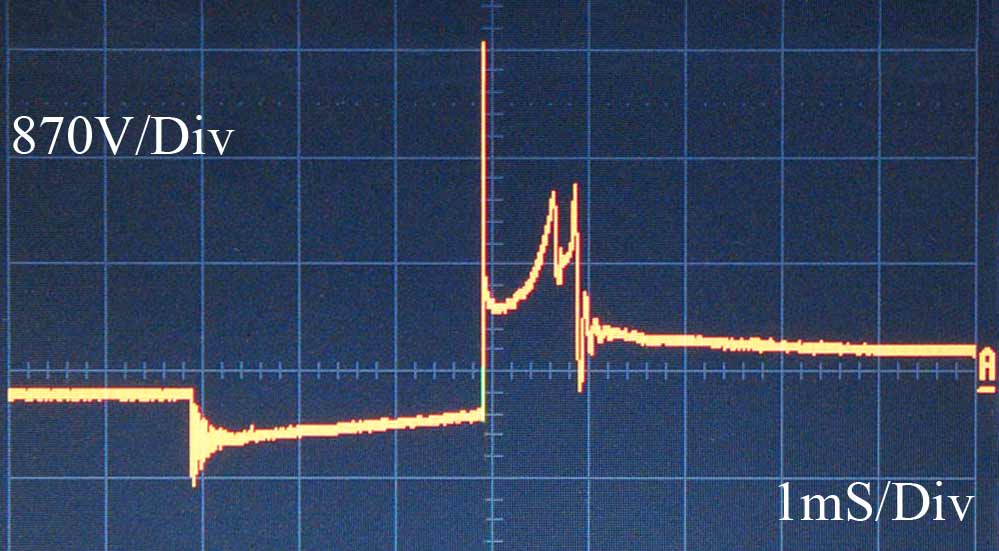

This shows the same cylinder several cycles later but with a ragged burnline. This is caused by the cylinder going lean in the middle of the burn and the coil, with enough energy left, re-igniting the cylinder. The burn ends with the coil having excess energy and the burntime slightly shortened.

Running dynamic compression testing

Information to come later.1BitHigh only deals with and perfoms testing on static engines. For in-cylinder testing please do get in touch.