Case study - Musical Fidelity A370 rebuild

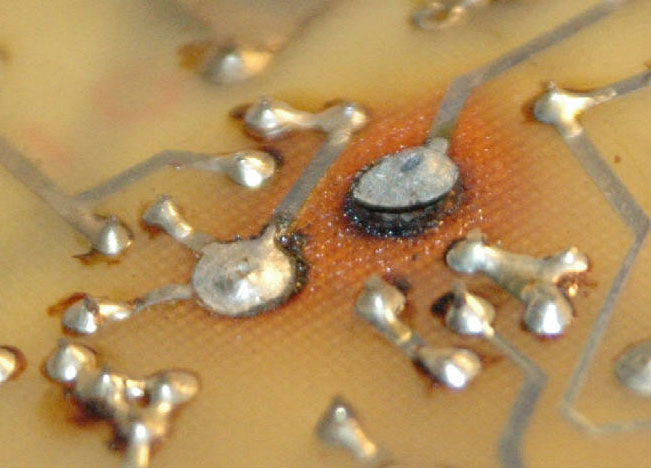

The Musical Fidelity A370 was one of the best loved power amplifiers of British origin. It's smooth effortless power delivery made listening to music a real pleasure. Given the operating temperature and some of its design it's a wonder that these have kept going as long as they have. Many have suffered from thermal damage and its associated effects. The main electrolytic power supply capacitors often dry out, some of the solder joints fatigue and go dry. The output devices tend to loosen up over time. That said it's a wonder these continue to sound as good as they do, even in a poor state. A complete overhaul is recommended before a fault occurs that causes a lot of damage, especially as the original output devices now are in short supply.Initial state

Due to the likelihood of a serious failure pushing the amplifier beyond repair it was decided to completely rebuild it.

Rebuilding

The results

The new soft start circuit markedly reduced the inrush current. The soft start was now voltage dependant and the new sequence had a proper response in the case of mains supply brown outs. Previously this amplifier would not survive being run with anything less than a 10A fuse in the plug. Now the initial inrush was limited to 5A peak whilst the capacitor bank acquired about 1/2 of its charge. The blown incandescent lamp in the power on switch was replaced with its modern solid state equivalent. In all, an already heavy amplifier gained just under 7Kg in weight. Even though the case was much more tightly packed, thermally the amplifier was happier.

Testing of it from an electronics point of view for frequency response, phase response / correct phase and stability into complex loads completed its testing.

Side note: A couple of people have pointed out that the front of this amplifier isn't marked as a Mk2. It was a Mk2 inside. There seems to be quite a few variants of these about. Different markings, different boards in them and different capacitor racks.